Zero emissions are produced during electric aircraft flight, and electricity can be produced from low or no-carbon sources. Green aviation satisfies stricter emissions regulations, and will not be subject to emissions/fuel taxes.

Electric aircraft have 30-50% lower operating costs compared to traditional combustion aircraft. Refuelling with hydrogen is likely to cost ~ 50% of kerosene, and recharging batteries is likely to cost 5-10x less

Electric aircraft are 90% efficient while conventional combustion aircraft are only 35% efficient. Investment in battery technology is booming for electric mobility and primary energy storage, never so high worldwide

Attractive to climate-conscious consumers, such as the 46% of passengers who would pay ≥2% or more for carbon-neutral flights. Lower noise emissions increase possible locations served, providing passengers with greater travel flexibility

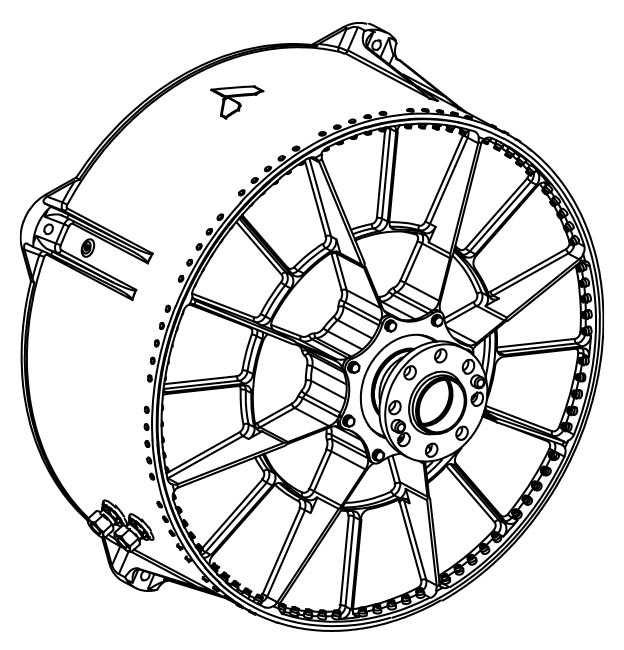

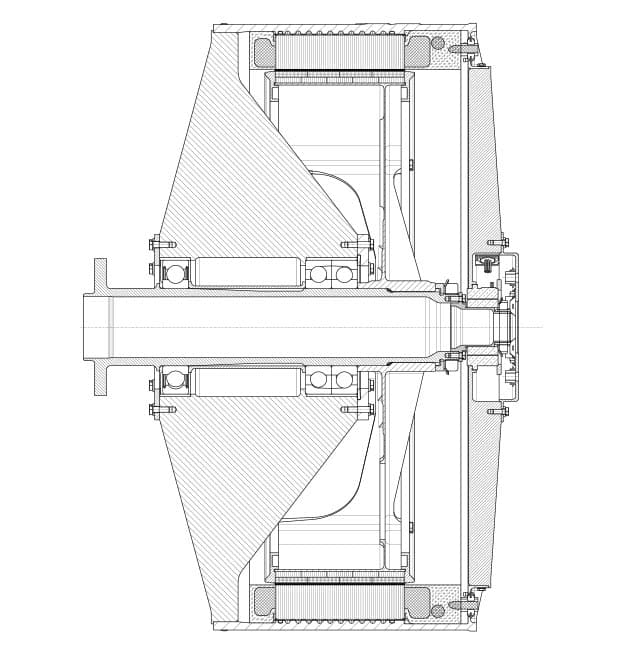

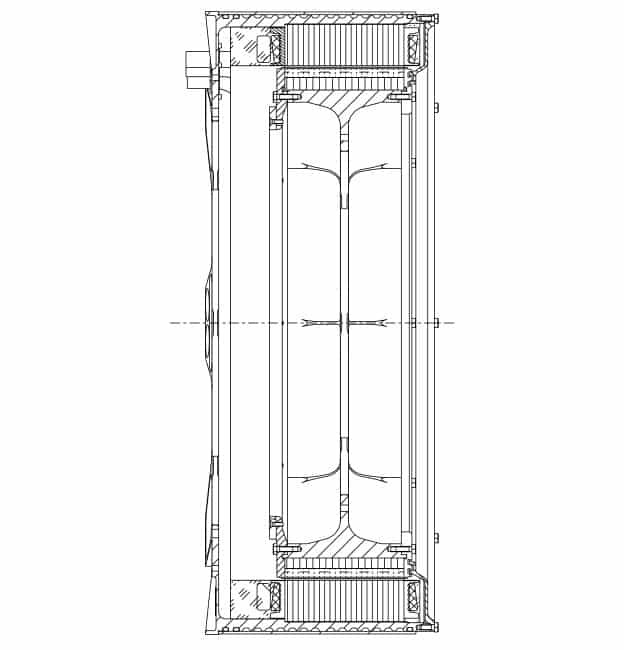

The ET-6 high-density electric propulsion motor, engineered by PMC, matches the power output of a PT6 turboshaft with only 115 kg of mass. It maintains the same propeller interface and reaches speeds of up to 2200 rpm, with peak power exceeding 750 kW.

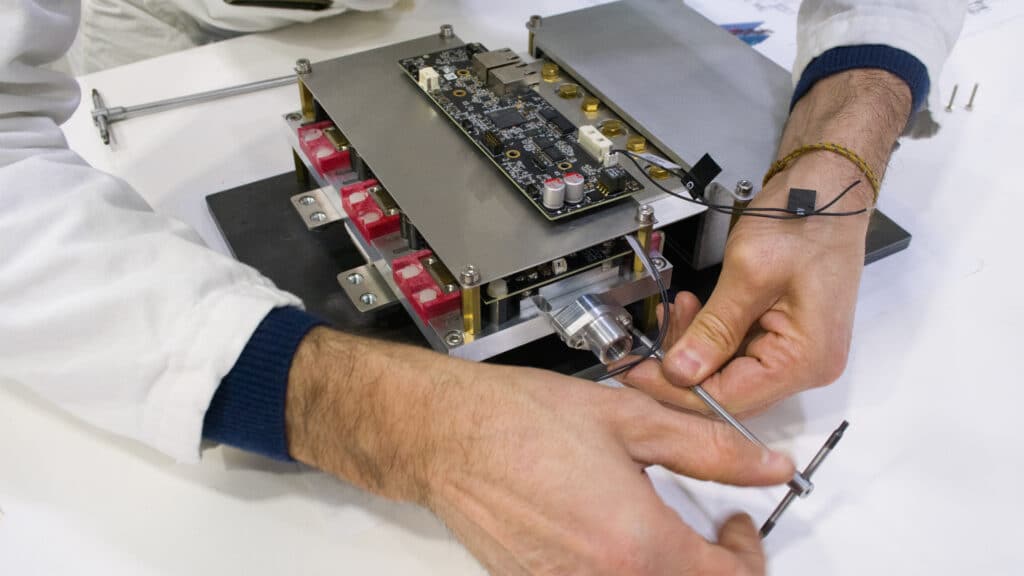

Thanks to its direct connection to the propeller, the ET-6 eliminates the need for a gearbox. The only components requiring maintenance are grease-lubricated hybrid bearings, inspected after 5000 hours of operation.

The rotor uses permanent rare-earth surface magnets, secured by a preloaded carbon fibre ring. This ensures constant compression, even under overspeed conditions, increasing safety and durability.

Additionally, the titanium alloy shaft reduces weight while maintaining strength. Its hollow structure houses the governor mechanism, optimizing space. To minimize lubrication needs, the ET-6 uses hybrid angular contact preloaded ball bearings.

The high-efficiency liquid cooling system surrounds the stator, while the rotor remains uncooled, simplifying thermal management. Moreover, all structural components are made of high-strength light alloys, precisely machined from solid blocks without welds or castings.

From an electrical perspective, civil aviation adopts automotive-grade standards with battery voltages ranging from 850 to 650 VDC. This approach leverages the wide availability of optimized semiconductors. However, a 2000 VDC standard for large aircraft may emerge in the future.

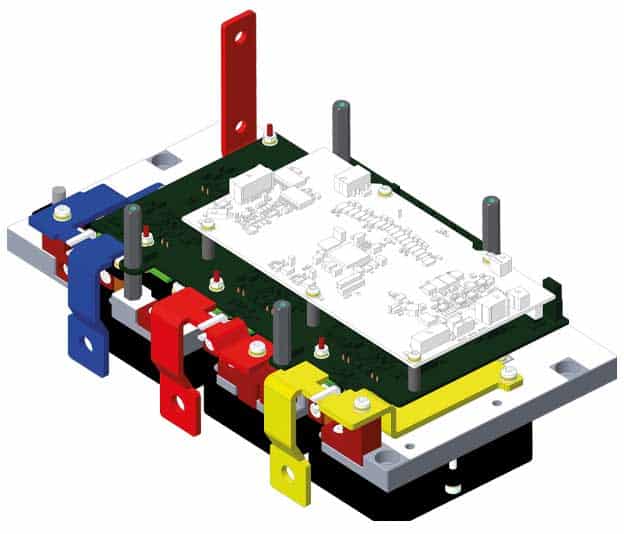

To enhance safety and system availability, the ET-6 divides its motor winding into four independent sections. Each section operates as a separate motor, limiting current to 400 A per unit. Consequently, this design improves redundancy and optimizes drive size for better reliability.

In hybrid solutions the compact electric motor operates at full power during take off allowing for the downsizing of the conventional internal combustion engine and then can be used at lower power, or as a generator during cruise operation

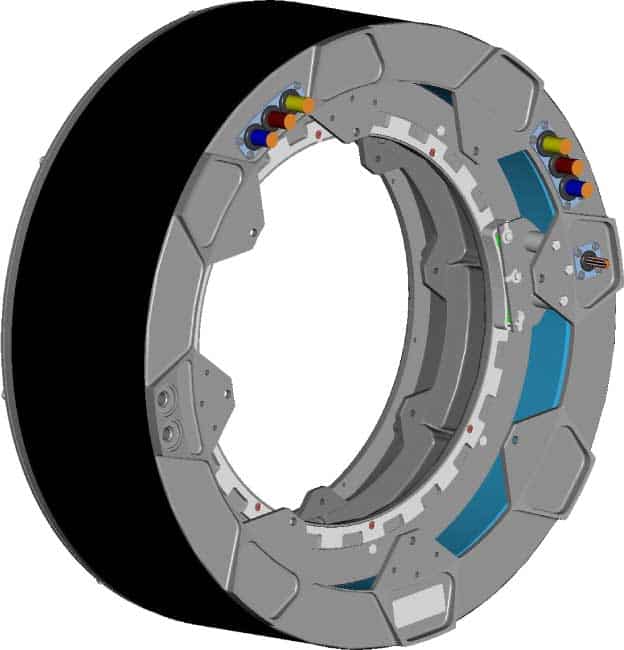

Frameless hybrid permanent magnet motors are specifically designed for direct installation on the propeller axis, which connects to an IC or turboshaft engine. During take-off, the combined power of the IC engine and the electric motor—fed by a compact battery—delivers the necessary starting force.

The motor features a slim ring design without bearings and uses external cooling. Permanent FeNdB magnets sit on the rotor’s surface, firmly held by a preloaded carbon fibre ring. The stator includes two independent windings, enabling control through two separate drives.

High-Power Inverter for Electric Propulsion